EEMB Battery Quality Control & Compliance

As a professional lithium battery manufacturer, the implementation of quality control (QC) measures is one of the most important steps to ensure that the lithium batteries produced meet customer requirements. Quality control (QC) refers to all actions taken by a company to verify that its products meet specific quality standards. According to ISO9001, it is "part of quality management, focusing on meeting quality requirements", and it usually involves inspection and testing. Quality control focuses on the steps you take to identify defects before, during, or after the manufacturing process. Quality assurance (QA), ISO9001 defines it as "part of quality management, focusing on providing confidence in meeting quality requirements.”

#Why is Quality Control Important?

- Improve company reputation

- Comply with relevant standards and regulations

- Higher quality products

- Improve customer satisfaction, loyalty and retention

- Better brand recognition and distinction from competitors

Quality compliance is an important part of an effective quality control plan.

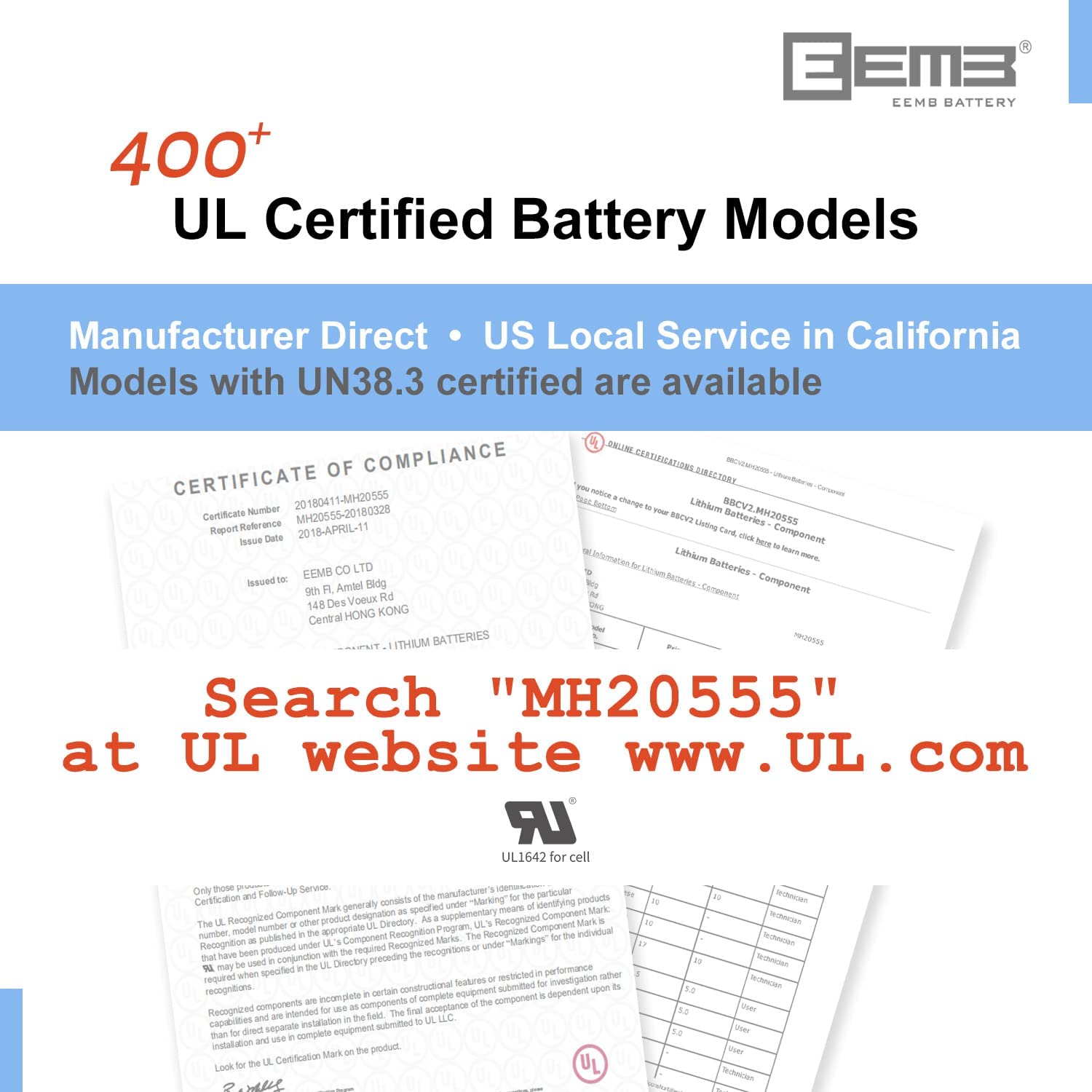

Quality compliance certificate for EEMB lithium battery :

UL1642, IEC, UN38.3, ISO9001, ISO14001, CE, GOST, KC, EN62133, PSE, REACH, TS16949, Military standard GJB 9001B-2009, Battery directive 2006/66/EC

Product inspection allows you to verify whether the lithium battery meets specific quality standards.

Types of product inspections, including:

- Pre-production inspection (PPI). Once the raw materials arrive at the factory, pre-production inspections will be carried out. They provide an opportunity to find problems with your materials before they are used to manufacture your products.

- During production inspection (DUPRO). The DUPRO inspection is carried out after at least 20% of the production is completed. This allows you to identify any errors in the goods shipped from the production line before the entire batch is affected.

- Pre-shipment inspection (PSI). This is the most common type of inspection, which is carried out after the product is 100% completed and at least 80% packaged. This inspection ensures that the product meets quality standards before shipment.

Any further question regarding our quality process and quality compliance, let our Customer Service to assist you with hassle free service.